Have you wondered what goes into designing custom medical cables?

Since the customer is at the heart of every business decision, we’ve developed systems and procedures here at ClearPath Medical to ensure that product development projects are completed not just in a timely manner, but also meet customer specifications and exceed expectations. From the start, we take a team approach.

The 10-Point ClearPath Medical Approach to Designing Custom Medical Devices

Point 1 – Determining Project Scope

The first step is understanding your project’s scope, which allows us to provide transparency into the design process and establish roles and responsibilities to successfully execute. As you might imagine, projects vary in scope. Here’s a list of several types of projects listed in order of ascending complexity:

- Build-to-print (BTP) cable assemblies using existing off-the-shelf (OTS) components and connectors

- Project transfer of existing custom cable assemblies (which include custom components and connectors) from an alternate supplier

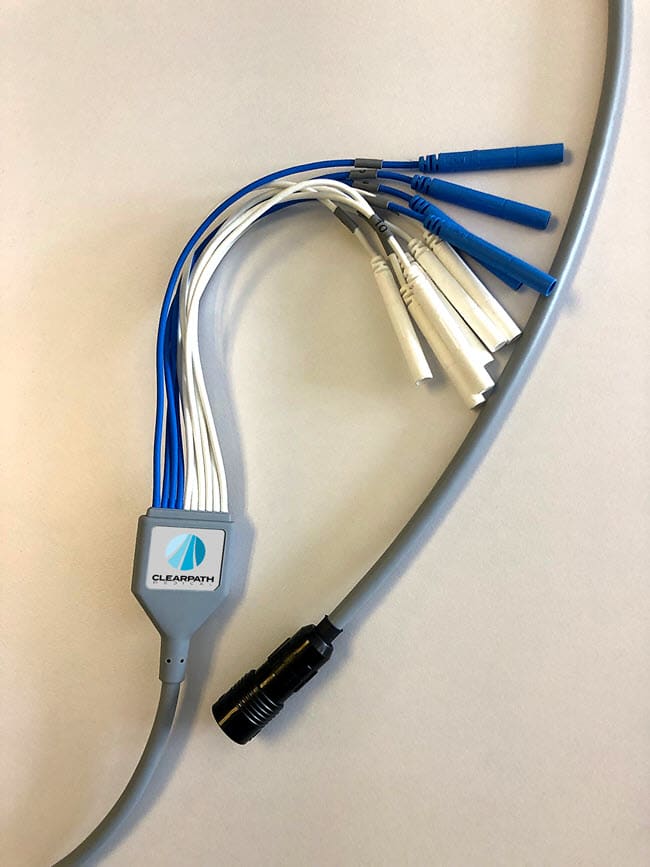

- Improvements to an existing cable assembly which will require re-design of custom components and/or custom connectors for improved manufacturability and/or product function

- New cable assemblies or interconnect systems which require custom components and/or custom connectors

Understanding our customer’s resource requirements is an important step towards successfully completing a new product development project.

Point 2 – Initial Project Review and Acceptance

Before taking on a medical device project and making any design or delivery commitments, we consider it critical to thoroughly review projects based on the following factors:

- Time to prototypes/Time to market – we like to move fast but are realistic. Does the lead-time for your program and its deliverables match the allotted time frame for clinical trials and production release?

- Capability match – are the requirements of your project, including engineering and manufacturing within the capabilities of the company? Do the products being manufactured fall within the scope of our business and registrations?

Point 3 – Development of Quotations and Proposals

Quoting a new cable or cable system requires communication with our OEM customers.

Understanding the Soft Requirements

While some projects include drawings, specifications, and even a bill-of-materials (BOM), it’s essential to have a conversation to understand the “soft” requirements. This means understanding how the product will be used and who will use it (i.e., our customer’s end-user). Often there are expectations for the product that aren’t stated in the supplied documentation that may ultimately influence the design of the product.

What’s the Target Cost of the Product?

Another important consideration is the target cost of your product. Knowing the target cost will allow the product to be designed and engineered with materials and components that can likely meet the target with consideration of assembly or device life cycle.

When a target cost isn’t available, it’s often best to offer a budgetary quotation. A budgetary quote can help a prospect understand what non-recurring engineering development costs (NRE), including non-recurring tooling (NRT) may be, as well as an estimate of production pricing. We find budgetary quotes that are in-line with customer’s expectations generally leads to a formal quotation or proposal.

Pricing for sourced raw materials and components, depending on how complex, may be available quickly but also may take some time. While we obtain this information, engineering determines the processes needed to manufacture the part(s) and will estimate the NRE and NRT, assembly fixtures and any unique test equipment required. Once the cost of materials and time to manufacture is known, we can prepare a quotation and present it to our customers.

Point 4 – Establishing Project Teams and Kick-Off Meeting

Once we receive a purchase order or other suitable commitment from customers, we schedule a project kick-off meeting with our new OEM customer and the assigned project team at ClearPath Medical. Successful new product development projects result from teamwork – teamwork between both parties.

At a minimum, the project team should include representatives from engineering, quality and materials/customer service. During the kick-off meeting, we will establish a point-of-contact for both parties.

Point 5 – Collaborative Team Meetings

Regular communication is one of the keys to successful new product development projects. To facilitate communication, your team at ClearPath Medical will establish regular team meetings, conducted either by phone or web-conference on a weekly basis (unless otherwise directed by our partners).

We don’t want there to be any surprises for our OEM partners. Holding regularly scheduled team meetings, publishing action items, and putting together clear-cut project plans that are continually reviewed at each meeting helps keep everyone on track.

Point 6 – Gathering Design Inputs

One of the most important aspects of a new medical cable design project is design input.

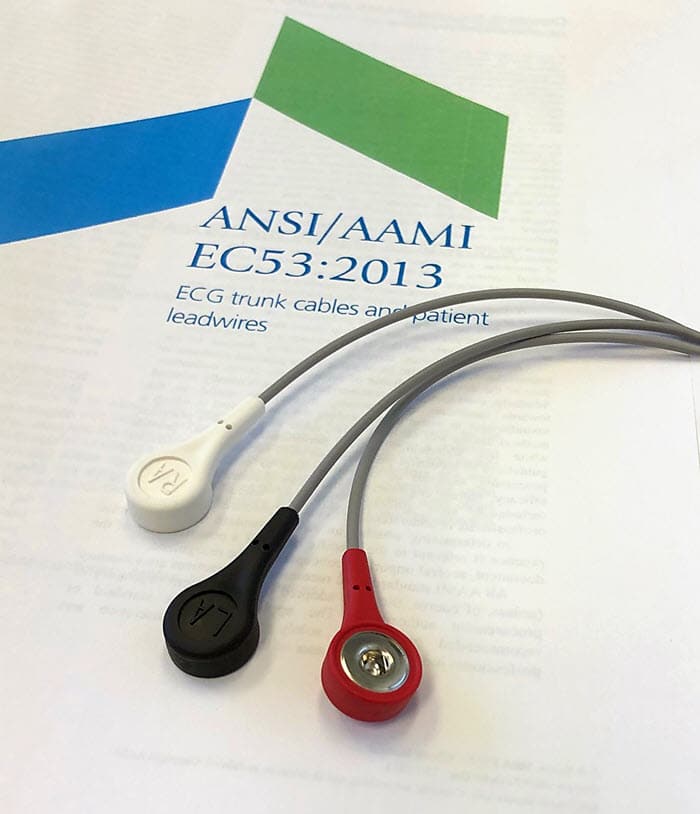

Design inputs are the electrical, mechanical and environmental requirements of the device that will be used as a basis for device design and product qualification. In addition to electrical, mechanical and environmental requirements, it’s important to understand how your product is intended to be used. More specifically, but not limited to:

- What need is the new cable assembly fulfilling?

- Where and by whom will the device be used?

- What other devices will the new cable assembly interface with?

- How long is the assembly expected to last and under what conditions, including sterilization and cleaning?

- What safety, regulatory and industry standards is the device required to comply with?

- What labeling and packaging are required?

There’s no such thing as too much information. Informing our design team of how the device will be used ensures that the finished product will meet all customer and user requirements.

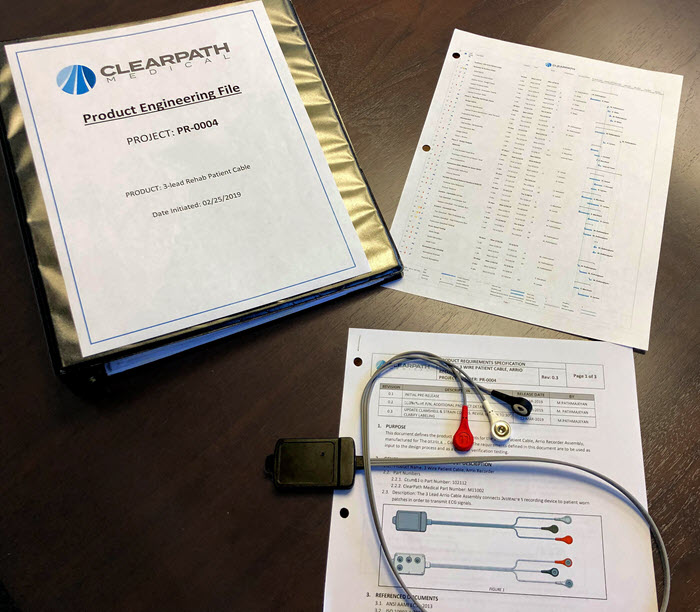

Point 7 – Drafting Product Specifications

Once we’ve obtained sufficient design input and understand it fully, we can draft product specifications.

The product specification should be as detailed as possible and should include all electrical, mechanical and environmental characteristics and requirements. If you’re interested in viewing a sample product specification, request it here.

Point 8 – Design Reviews

Throughout the development process, ClearPath Medical will participate in design reviews in compliance with our customer’s design control processes.

If new mold tooling is required for the project, we will share CAD 3D models, 3D printed samples or machined prototypes for approval before tool fabrication is begun. This establishes a certain confidence level for freezing the design in order to start cutting tooling.

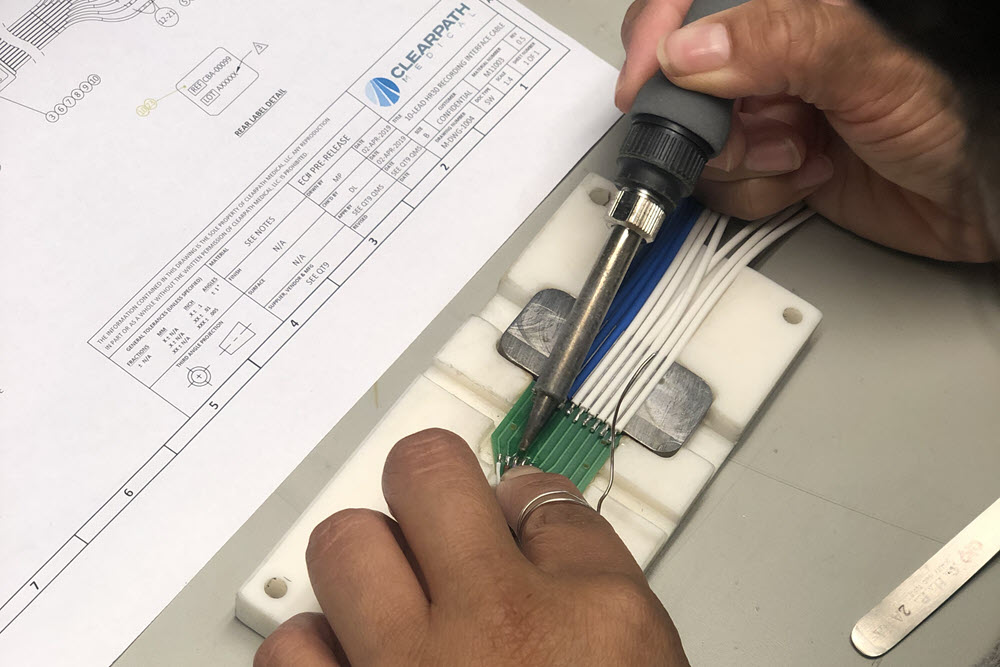

Point 9 – Ensuring Product Qualification

All new cable development projects require some level of qualification. Some require only design verification while others also may require process qualification if new processes are introduced.

Design verification testing is necessary to confirm that the finished product meets the product’s requirements. Design verification testing (DVT) is quoted as part of non-recurring engineering charges (NRE). The ClearPath Medical team will draft a DVT protocol based on the product specification and other input. Once approved internally, will share it with our OEM partner for their approval.

Once the protocol is approved and initial parts are manufactured, test protocols are executed and the results are reported to all team members. ClearPath Medical maintains a fully equipped lab to accommodate most design verification tests including:

- Hi-Potential (HiPot) electrical / Dielectric Withstand

- Mechanical flex, tensile, insertion/extraction (mate/unmate)

- Cleaning agent compatibility testing

We are also experienced in Production Part Approval Process (PPAP) – a process adopted from the automobile industry into the medical device industry which confirms that the product can be consistently manufactured and meets all critical requirements. Because PPAP requirements vary, we will quote them as a separate non-recurring engineering charge. Lastly, since we are ISO 13485-2016 certified, we are aware that it includes elements of PPAP and the following:

- Design Failure Modes and Effects Analysis (DFMEA)

- Process Flow Diagram

- Process Failure Modes and Effects Analysis (PFMEA)

- Control Plan

- Part Submission Warrant (PPAP Summary)

When considering your project timeline, it’s important to keep qualification activities, like PPAP and DVT testing, in mind. These items are critical and should be addressed during the early stages of our project planning as they may have a significant impact on the overall project timeline.

Point 10 – Creating an Accurate Project Timeline

One last key to a successful project is an accurate project timeline.

ClearPath Medical favors Microsoft Project® to record and track project milestones and responsibilities. Our engineering team will establish a project timeline and continually review and revise it to ensure each deliverable accurately reflects it’s current status and meets our customer requirements, timeline, and expectations.

Recapping How ClearPath Medical Designs Custom Medical Devices

Successfully designing and manufacturing medical devices such as cable assemblies and interconnects requires a team approach – a team made up of both the OEM device owner and ClearPath Medical. All of your requirements will be incorporated into controlled and audit-able documentation resulting in a high-quality medical device that can be manufactured repeatedly, consistently and delivered in a timely manner.

If you would like additional information on how ClearPath Medical can help with a medical device or cable assembly interconnect project, contact us for more information. We get back to our inquiries within 24 hours or less.

Curious about the markets we serve? Download our latest Solution Brief.

Thanks for reading!