Low-Noise Cables Explained

Reducing unwanted interference is important for accurate and dependable measurements when it comes to medical cable assemblies and signal transmission.

This month’s ClearPath Medical blog explores the uses and benefits of low-noise medical cables and the significance of minimizing unwanted interference for precise and reliable measurements in medical cable assemblies and signal transmission.

A low-noise cable excels at minimizing motion-induced noise, surpassing even electrical noise reduction. These specially crafted cable assemblies, such as over-molded or other medical cable assembly variants, are meticulously designed to effectively reduce unwanted electrical noise and electromagnetic interference. This guarantees that the quality of transmitted signals remains unaffected.

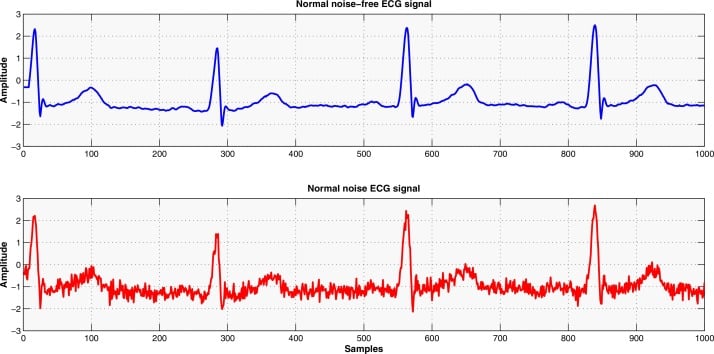

Figure 1: Example of a noise-free ECG signal and a normal noise ECG signal

(Source: sciencedirect.com)

Different Types of Low-Noise Cables

Common examples of medical cable assemblies that require low noise include EEG, ECG, and Pulse Oximetry. These applications often demand accurate and clear signal transmission, making low-noise cables essential for maintaining signal integrity.

How Much Noise Reduction Is Required?

The voltage carried by a low-noise cable can vary. Typically, it ranges from a few microvolts to several millivolts. For instance, in the case of ECG signals, they carry between 0.5-5 millivolts, while EEG signals can range from a few microvolts to several microvolts. Lastly, EMG signals typically range from 10-100 millivolts. It’s important to note that the cables themselves don’t generate voltage; they simply carry the signals produced by the medical devices.

To put it into perspective, a low-noise cable can reduce noise from 15-250 microvolts!

For more information, read our blog about triboelectric noise.

How Low-Noise Cables Are Made

Low-noise cables require specific shielding and insulation techniques to prevent interference with the signals. To reduce noise, graphite or silver wrap is often applied to the outer surface of the dielectric layer. A conductive layer is then added to the surface of the primary insulation, which is bonded to the insulation. This additional layer prevents any movement between the materials and ensures no changes occur.

Difference Between Standard and Low-Noise Cables

The main difference between a standard cable and a low-noise cable is their shielding. While a standard cable lacks special noise-reducing features, a low-noise cable sometimes uses a unique coating called Ethylene Tetrafluoroethylene (ETFE). ETFE possesses excellent electrical insulation properties and is highly resistant to chemicals, heat, and other environmental factors. This coating significantly reduces static electricity when the cable’s shield rubs against the conductor during motion.

Can You Still Make a Low-Noise Cable Without ETFE?

Yes! It’s possible to make low-noise cables without using ETFE. While ETFE is a common choice for special conductive coating in low-noise cables, there are other materials and approaches available to reduce noise.

Alternative materials like conductive polymers or metal-based coatings can be used to provide the required shielding properties. These materials can effectively minimize static electricity and reduce electromagnetic interference.

Moreover, the design and construction of the cable can incorporate various techniques to enhance noise reduction.

What Other Kinds of Techniques Can Be Used to Reduce Noise?

Low-noise cables also use advanced methods for insulation, impedance control, connector quality, and rigorous testing to ensure minimal interference and better performance.

The insulation used in low-noise cables is selected with great care to minimize noise and preserve signal integrity. The following are types of insulation commonly used:

- Dielectric Insulation

- Foamed-Polyethylene Insulation

- Shielding

Impedance control methods help maintain signal integrity and reduce signal reflections. High-quality connectors minimize signal loss and provide a reliable connection. Thorough testing is performed to ensure that low-noise cables meet strict requirements for accurate signal transmission.

Maintaining a Clean Signal: One Aspect of Signal Integrity

Reducing unwanted interference, as discussed earlier, is crucial for accurate and dependable measurements in medical cable assemblies and signal transmission. However, it is important to note that minimizing noise is just one aspect of maintaining a clean signal. To ensure comprehensive signal integrity, various factors need to be considered, including compliance with relevant standards and proper testing methodologies.

ANSI/AAMI EC53 and Signal Integrity

When it comes to evaluating and maintaining signal integrity, one widely recognized standard is The Association for the Advancement of Medical Instrumentation and American National Standards Institute (ANSI/AAMI). ANSI/AAMI EC53 specifically, provides guidelines and test procedures for assessing the electrical performance of cables and connectors used in medical applications. This standard helps ensure that medical cable assemblies meet the required specifications for signal transmission.

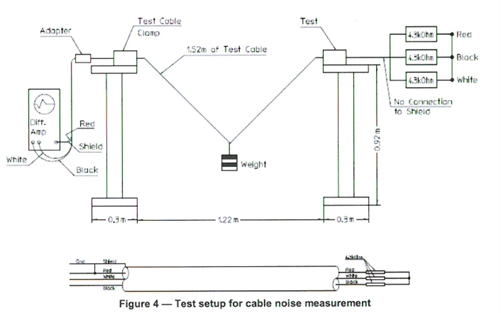

Test Setup:

- Figure 4 of the EC53 standard illustrates the test setup. A compliant set-up should be 36 inches high with heavy gauge steel posts mounted into a concrete or other sturdy floor set five feet apart, center-to-center. A one-half inch thick steel plate is centered on the top of each post allowing 5 feet of cable or wire to be held firmly between clamps set 48 inches apart. Care must be taken when setting up the test area, to ensure it’s away from interference with electrical panels, large electrical motors, vehicle traffic or foot traffic. Attached at the center of the test unit is a weight that equals 40x the weight of one foot of cable or wire. When ready to test, a qualified test technician will hold the weight at the level of the clamps and drop the sample. The peak-to-valley voltage measurement is taken using a digital oscilloscope with pre-amplified signals. The resultant value must be less than 50µ volts.

Wrapping Things Up

In medical applications, it’s crucial to utilize low-noise medical cables for precise and reliable signal transmission. These cables efficiently decrease unwanted interference, resulting in a clear and accurate signal transmission that significantly improves the quality of medical treatments and diagnostics. With the use of specialized construction methods and materials such as graphite or silver wrap, and coatings like ETFE, medical cable assemblies can attain unparalleled levels of noise reduction. Therefore, medical professionals can rely confidently on the exceptional outcomes that low-noise cables provide.