GETTING TO KNOW YOUR SHIELDING OPTIONS FOR MEDICAL CABLE ASSEMBLIES

A few months back we talked about the importance of cable jackets for medical cable assemblies, as it helps achieve the optimal environmental performance requirements. We’re going a layer deeper in this blog and exploring shielding options. Much like going through the Earth’s layers, down into the magnetic core, there are also important magnetic fields that assist the overall integrity of a medical device. Medical cables and lead wires can act as unintended antennas to both receive and radiate electromagnetic interference (EMI) signal shielding which is often necessary and an important consideration of medical cable design.

You might be wondering, what are shields? Shields are additional conductors added to wire or cable to help isolate the electromagnetic fields of conductors within the shield from those outside of the shield. Shields may be placed over individual conductors, groups of conductors, or the entire bundle of conductors within the cable.

The most common location for a shield is immediately below the cable jacket. However, more complex medical cables may be made up of several components (sub-cables) with one or more shields.

Shielding helps prevent unwanted external interference but is often used to prevent internal signals from interfering with each other within the cable. This becomes a more significant issue when a medical cable carries both power and signal lines, which is common for many medical device applications.

Let’s take a look into the different types of Shielding:

#1 – BRAIDED SHIELDS

Braided shields provide excellent protection from both high and low frequency interference all while maintaining good flexibility and flex life.

Braided shields are typically made up of groups of fine copper strands and are usually tinned. They are typically made up of two groups woven in opposite directions; one group is applied in a left-hand lay and other in a right-hand lay. Because of this design, a braided shield offers good flexibility, approaching that of a spiral shield.

Most medical cables incorporating a braided shield specify 80 to 95% shield coverage. The higher the percentage of braid coverage, the more effective the EMI shielding is. Coverage of 100% is not possible with a braided shield because leakage will always occur at points where the strands cross each other.

In addition to the percentage of coverage, the tightness of the braid affects performance. A tight braid with a high percentage of coverage does a better job of shielding, but will make the medical cable less flexible. A looser braid offers greater flexibility, but comes with reduced effectiveness of the shield.

When it comes to termination during the manufacturing process, braided shields can be difficult to terminate because the braid has to be “combed out and pigtailed.” This extra labor can add cost to the overall medical cable assembly. We suggest running a drain wire down the length of the shield is used to make termination of the shield easier.

For applications requiring a very high number of flex cycles, a braided shield may not be the best choice. The braid will occasionally break down due to the cross lapping strands abrading each other. When this happens the broken strands can damage insulation with continued flexing. We always recommend taking in the medical device’s desired service life into consideration when selecting the shielding option.

#2 – SPIRAL SHIELDS

A spiral shield, also known as a serve shield, consists of wire (usually tinned copper) wrapped in a single-layer spirally around one or more insulated conductors.

Spiral shields typically offer increased flexibility and flex life when compared to a braided shield and include about 90 to 95% coverage. They are also easier to terminate and are most effective at providing low frequency protection.

#3 – FOIL SHIELDS

A foil shield consists of metallic foil, typically aluminum, laminated to a film such as polyester or polypropylene.

Foil shields provide 100% coverage with the foil typically wrapped in overlapping layers around the cable core. The 100% coverage is a physical property and does not mean that a foil shield provides 100% EMI shielding. Foil shields are effective at shielding both high and low frequency interference. Foil shields are lighter weight, less bulky, and typically add less cost to a medical cable assembly when compared to braided shields.

Foil shields may be more flexible than a braided shield but typically have a shorter flex life. A drain wire, which runs the length of the cable in contact with the foil shield, makes a reliable electrical termination of the shield possible.

#4 – COMBINATION SHIELDS

Combination shields consist of more than one layer or type of shielding and provide maximum shield efficiency across a wider frequency spectrum.

The combination braid-over-foil combines the strength and flexibility of a braided shield with the advantages of 100% coverage of a foil shield.

COMPARISON OF TYPES OF SHIELDS

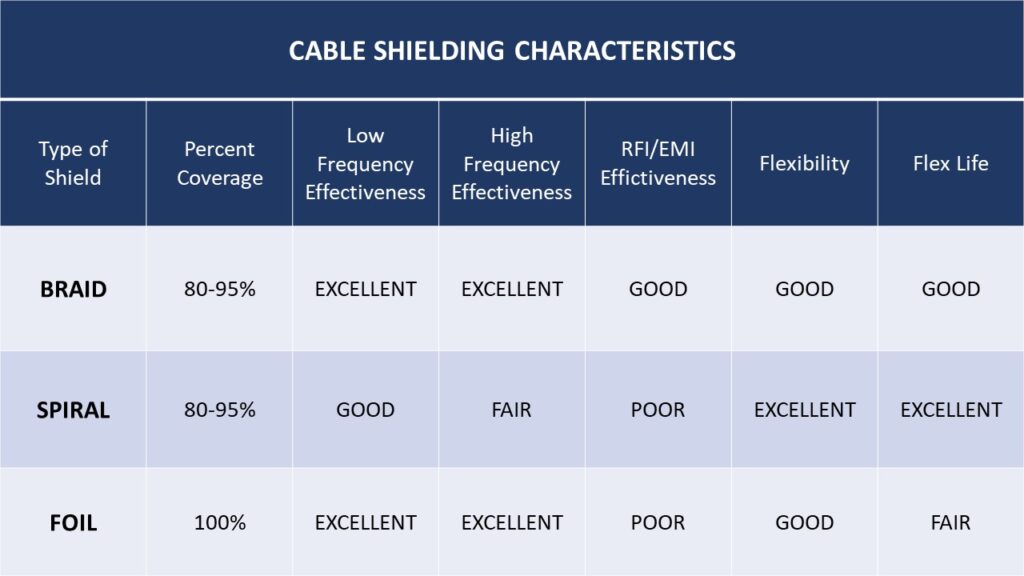

The following chart offers a comparison of the three types of shielding discussed and a summary of electrical and mechanical performance for each:

SUMMARY

Medical cable assemblies can present some unique challenges due to the need to meet patient safety standards, but also because of the general nature of physiological signals.

EMI and Radiofrequency (RF) interference can degrade signals carried by medical cables making diagnosis difficult or even impossible. Effective shielding can reduce unwanted interference and reduce the amount of electronic filtering needed within the device.

All cable assembly elements of a medical device play an important role in meeting product performance, usage, environmental requirements and aesthetics. The team at ClearPath Medical has the experience and expertise to assist you in designing medical cable assemblies with appropriate and adequate shielding for your specific application.