The Importance of Certifications: ISO:13485 & FDA OVERVIEW:

Read time: 5 minutes

When thinking about cable assemblies, who actually knows about its ISO regulation requirements?

When it comes to Medical Cable Assembly manufacturing, there may be certifications needed to supply assurances that standards are being consistently met. Though it may be known that certifications are needed, it may not be clear why they are needed.

This month’s ClearPath Medical blog will be an overview of ISO 13485 certifications and requirements stipulated by the Food and Drug Administration (FDA) to assure the confidence and knowledge needed when developing medical cable assemblies or partnering with a medical manufacturing company!

What is an ISO Certification?

The International Organization for Standardization (ISO) is a worldwide federation of national standards bodies. The process of preparing International Standards is performed by ISO technical committees. Other organizations such as international, governmental, or non-governmental also take part in ISO. In addition, ISO works with the International Electrotechnical Commission (IEC) on any electrotechnical standardization affairs.

International Standard expects that the organization:

- — identifies its role(s) under applicable regulatory requirements.

- — identifies the regulatory requirements that apply to its activities under these roles.

- — incorporates these applicable regulatory requirements within its quality management system.

What does ISO 13485 Mean?

ISO 13485 specifically, is a certification that specifies requirements for a quality management system (QMS) in an organization that supplies proof of ability to meet regulatory requirements. This system applies for organizations that engage in one or more stages of the life cycle of a medical device. These requirements apply to all organizations, no matter the size.

It all begins with management support and finding the customer requirements for the QMS. The organization will need to start developing documentation which includes items such as: Quality Policy, Quality Objectives, and Quality Manual. Together, these define the overall scope and implementation of the Quality Management System. In addition, to deliver a product or service from an organization, they will need to create mandatory and added processes and procedures, as necessary.

What are the requirements do I need to know?

To better explain, here is a quick run-down on what to expect when reading through ISO 13485 requirements:

The most up-to-date version of ISO 13485 is from 2016. This version includes several updates such as: focus on risk, clarification of management responsibilities, clarification of training responsibilities, improvement to the facility requirements, better alignment of design and development requirements to regulations, more emphasis on control of suppliers, requirements for traceability procedures, addition of complaint handling, and enhancement of product cleanliness requirements.

What about other ISO standards?

It is common to see other manufacturers with certifications in ISO 9001 or ISO 9001:2008. Having an ISO 9001 certification corresponds with ISO 13485:2016. ISO 9001 is an internationally recognized standard for Quality Management Systems (QMS) published by ISO. Although the ISO 13485:2016 standard came out after the major update of ISO 9001:2015, the ISO 13485 standard does not align with this newest version of ISO 9001. Instead, the most recent changes of ISO 9001:2015 resulted to not be necessary for medical devices.

Next, let’s dive into FDA regulations with medical assemblies.

What is the FDA?

The Food and Drug Administration (FDA) is known for being the oldest consumer protection agencies in the United States. Regulations began its first practice in 1848. It originally started as a practice for chemical analysis for agricultural product safety. However, the Department of Agriculture bought the practice in 1862, and eventually, by the FDA.

So, the FDA isn’t just for food and drug regulation?

Yup, that’s correct! It’s used for medical devices, too!

Originally known as the Pure Food and Drugs Act in 1906 signed by Theodore Roosevelt, its purpose was to implement a law preventing interstate commerce in contaminated and falsely labeled food and drugs. The FDA’s long history has expanded its role in protecting the development of human and veterinary drugs, bio products, medical devices and radiation emitting products, human and animal food, and cosmetics.

Timeline of FDA and Medical Assembly Relationship:

1960’s/70’s: The protection of medical devices began. The Medical Device Amendments to the Federal Food, Drug and Cosmetic Act manifested from Congress.

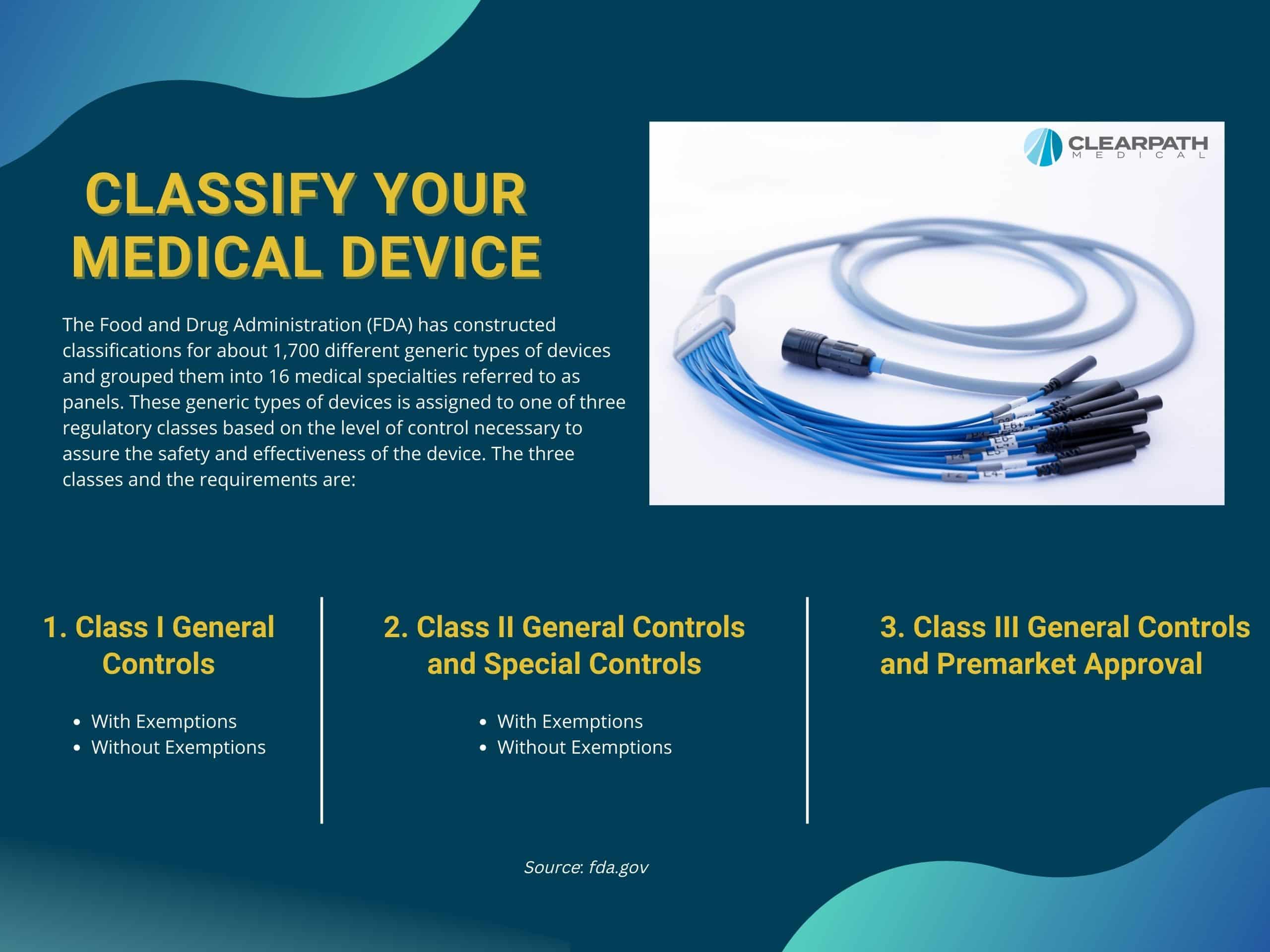

1976: the intention for this was to supply reasonable assurance of the safety and effectiveness of medical devices. The FDA created a three-class, risk-based classification system applying for all medical devices.

1982: The FDA began to regulate medical devices and radiation emitting products. This then formed the Center for Devices and Radiological Health organization.

The FDA created a compliant course of action for new medical devices (not on the market or noteworthy modifications) to allow premarket approval and premarket notifications.

Finished vs. Unfinished Medical Devices

Now having more insight between ISO 13485 certification and FDA requirements, another question comes to mind, what constitutes as a finished device and an unfinished device? According to the FDA, what distinguishes a finished versus unfinished medical devices are as follows:

- Per 21 CFR 807.65(a), Manufacturers of components, which are not otherwise classified as a finished device, which are distributed only to a finished device manufacturer, are not required to list those devices.

- Per 21 CFR 807.20(a)(6), Manufacturers of components or accessories that are ready to be used for any intended health-related purpose and are packaged or labeled for commercial distribution for such health-related purpose, e.g. blood filters, hemodialysis tubing, or devices which of necessity must be further processed by a licensed practitioner or other qualified person to meet the needs of a particular patient, e.g., a manufacturer of ophthalmic lens blanks, are required to register and list.

Wrapping Things Up

If at any moment the medical device fails, the consequences can be devastating or life threatening for a patient. More importantly, having certifications allow for breakdowns and damage for improved identification and tracking to help resolve issues more efficiently.

ClearPath Medical is both certified in ISO 13485 and registered with the FDA as a manufacturer to keep the highest standards when designing, developing, and manufacturing medical cable assemblies. Think we are a good fit for you? Or have any more questions about these requirements? Contact us to learn more.

The next time your company considers developing a medical cable assembly or any other medical device, check that their certifications and registrations are appropriately suitable!

Thanks for reading! Here are some more ClearPath Medical blogs that might interest you.

Love what you see? Sign up for our newsletter to get the latest updates on our company, worldwide and more.

Sources:

-

“A History of Medical Device Regulation & Oversight in the United States” Overview of Device Regulation, June 24th, 2019, accessed September 28, 2022

A History of Medical Device Regulation & Oversight in the United States | FDA

-

“FDA History” About FDA, June 29th, 2018, Accessed September 28, 2022,

FDA History | FDA

-

“Medical Devices—Quality management systems—Requirements for regulatory purposes” ISO 13485:2016, March 2016, accessed September 28, 2022,

ISO – ISO 13485:2016 – Medical devices — Quality management systems — Requirements for regulatory purposes