Supply chain management plays a crucial role to make sure devices and assemblies are delivered safely and effectively to patients.

In the world of medical devices and cable assemblies, the industry is tightly regulated and complex.

The supply network is a bit like the nervous system of the human body – vital for smooth functioning.

It involves the flow of information, data, and communication across different stages and entities, similar to how the nervous system transmits signals and coordinates actions throughout the body. Just as the nervous system enables the body to work as a cohesive whole, the supply chain process establishes quality, cost-effectiveness, and prompt delivery while mitigating risks of disruptions and regulatory issues, facilitating seamless operation of the entire business ecosystem.

This month’s blog will take a closer look at the unique aspects of supply chain management, exploring its critical elements and delving into the challenges and opportunities that arise in this specialized sector.

Understanding the Supply Chain

First, let’s get a basic understanding of what the supply chain does.

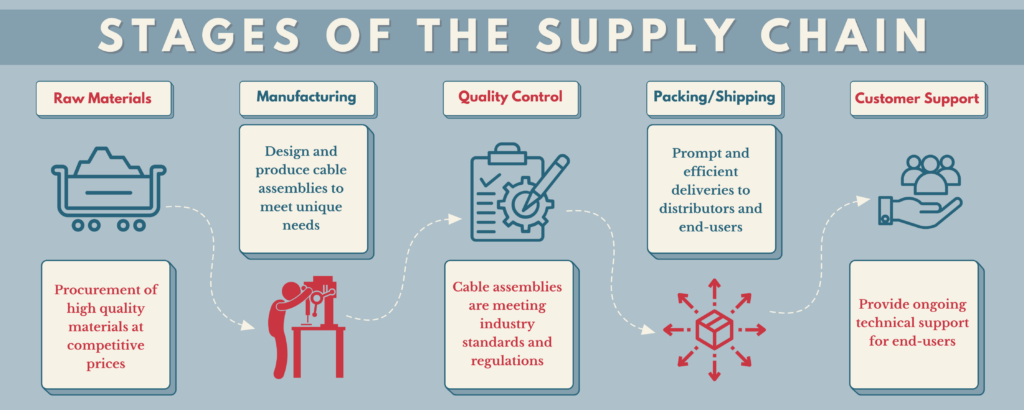

The supply chain refers to the sequence of processes involved in the production, distribution, and delivery of products from manufacturers to post market. It involves multiple stakeholders, such as raw material suppliers, cable assembly manufacturers, distributors, and end-users. Each stage of the supply chain process is essential to the success of manufacturing companies.

Here’s a breakdown of what each stage entails:

By carefully managing each stage of the supply chain process, manufacturing companies can ensure that they deliver high-quality products that meet customer needs and comply with industry standards and regulations.

Key Components of Effective Supply Chain Management

To make sure a product succeeds, it’s essential to have a solid supply chain management in place.

There are a few key indicators that can help make sure a supply chain is successful:

Strategic Sourcing

This means finding and choosing suppliers who can provide good quality materials and components at a fair price. Think about variables such as quality, cost, lead time, and reliability.

Supplier Relationship Management

This involves building strong relationships with suppliers. Being clear about what to expect from them, communicating well, and working together will help to develop new products and improve processes.

Inventory Management

This means managing the flow of materials and finished products through your supply chain. Keeping a close eye on inventory levels, keeping sure that nothing important is running out while also making sure that too much inventory isn’t sitting around.

Transportation and Logistics

Transportation and logistics play a pivotal role in ensuring timely and efficient movement of products. This involves figuring out the best way to move products around, whether that means selecting carriers or managing costs. It’s also important to make sure everything gets where it needs to go on time and in good condition.

By managing all of these pieces well, medical cable assembly manufacturing companies can be more efficient, save money, and make sure they’re delivering great products that meet their customers’ needs.

Challenges of Supply Chain Management

Managing the supply chain is important for any industry, but the medical manufacturing sector faces unique challenges that can make the process even more complex. These challenges include regulatory compliance, quality control, and supplier reliability.

Regulatory Compliance

When it comes to compliance, it’s a big deal to meet them.

The manufacturing and distribution of medical devices are subject to strict regulations by regulatory bodies such as the FDA. Companies must follow these regulations to make sure their products are safe and effective for patient use. If they don’t, they can face fines, recalls, or even legal action.

Read more about The Importance Of Certifications from our previous blog.

Quality Control

Without a structured quality control system in place, that’s asking for trouble.

Companies must make sure their products meet high-quality standards to ensure patient safety and avoid recalls. They also need to maintain quality control throughout their supply chain to make sure their suppliers meet their quality standards.

Supplier Reliability

Manufacturers depend on a network of suppliers to provide the raw materials and components necessary to make their products. If suppliers fail to deliver on time, provide defective materials, or go out of business, it can disrupt the entire supply chain and impact production schedules. This can damage a company’s reputation and cause it to lose customers. Product recalls due to quality issues can also be expensive and harmful to a company’s bottom line. When suppliers can’t deliver, it can lead to production delays that impact product availability and lead to lost sales.

Tips for a Smooth Supply Chain

To make sure medical assemblies arrive to customers on time and in top shape, manufacturing companies need to keep a good eye on how their supply chain is moving to avoid any roadblocks and slowdowns.

Here are some examples of how a well-managed supply chain should look like:

Quality Control and Regulatory Compliance Are A Must

Quality control and following the rules are key, and having programs in place to check that products meet safety and performance standards.

Keep up with industry regulations and certifications like ISO 13485.

Team Up With Good Suppliers

Suppliers = A manufacturer’s lifeline. Finding a trustworthy group of suppliers while building strong relationships so that all materials and products are shipped and arrive on time.

Use Technology to Track Inventory

Keep an eye on inventory with different means of technology such as: inventory management software’s, RFID tracking, and automated systems. This way, all items in inventory are being tracked in real time, and there will never be an issue of lost/missing materials and products.

Get Your Logistics and Transportation Plan in Order

Shipping on a timely basis is important! To make sure products get to customers quickly and efficiently, it is important to plan shipping methods, carrier selection, and transportation rules ahead of time. If products get to where they need to be as quickly as possible, it will help keep costs down.

Wrapping Things Up

Supply chain management plays a crucial role in ensuring safe and efficient delivery of products to patients. The supply chain process, much like the nervous system, coordinates and transmits information across different stages and entities through strategic sourcing, supplier relationship management, inventory management, and transportation and logistics. Despite its importance, the industry faces unique challenges such as regulatory compliance, quality control, and supplier reliability, making efficient supply chain management even more crucial. With a carefully managed supply chain process, medical manufacturing companies can enhance efficiency, save money, and ultimately improve customer experience with high-quality and standardized products.

ClearPath Medical is committed to being a reliable partner in this industry by having a well-managed supply chain that ensures high-quality products are delivered on time and in a cost-effective manner. As a result, our customers can trust us to deliver exceptional service and products that meet their needs.

Thanks for reading!

Contact Us for more information. We’re here to help. Let’s get started on your next medical cable assembly project, today!

Here are some more ClearPath Medical blogs that might interest you.

Love what you see? Sign up for our newsletter to get the latest updates on our company, worldwide and more.