Imagine a patient receiving treatment for a cardiac condition experienced a sudden cardiac arrest due to a faulty cable that went undetected during routine inspections. A single faulty medical cable can have dangerous consequences for patients.

Medical cable assemblies play a critical role in the delivery of life-saving medical procedures and treatments. Playing such a crucial role for treatments, it is vital to ensure these medical cables are the highest quality to minimize risk factors and failures.

This month’s ClearPath Medical blog will focus on the importance of inspection methods for optimal quality assurance.

Quality Control – Why We Need It

When it comes to quality control, it’s essential to maintain high-quality standards in the manufacturing process. This ensures that the cable assemblies meet strict safety, reliability, and performance standards. To achieve this, every stage of the manufacturing process, starting from raw materials to finished products, is closely monitored and tested. These considerations guarantee that the medical cable assemblies are complying with the necessary specs that are within industry standards.

Read more about, “The Importance of Certifications” from our previous blog.

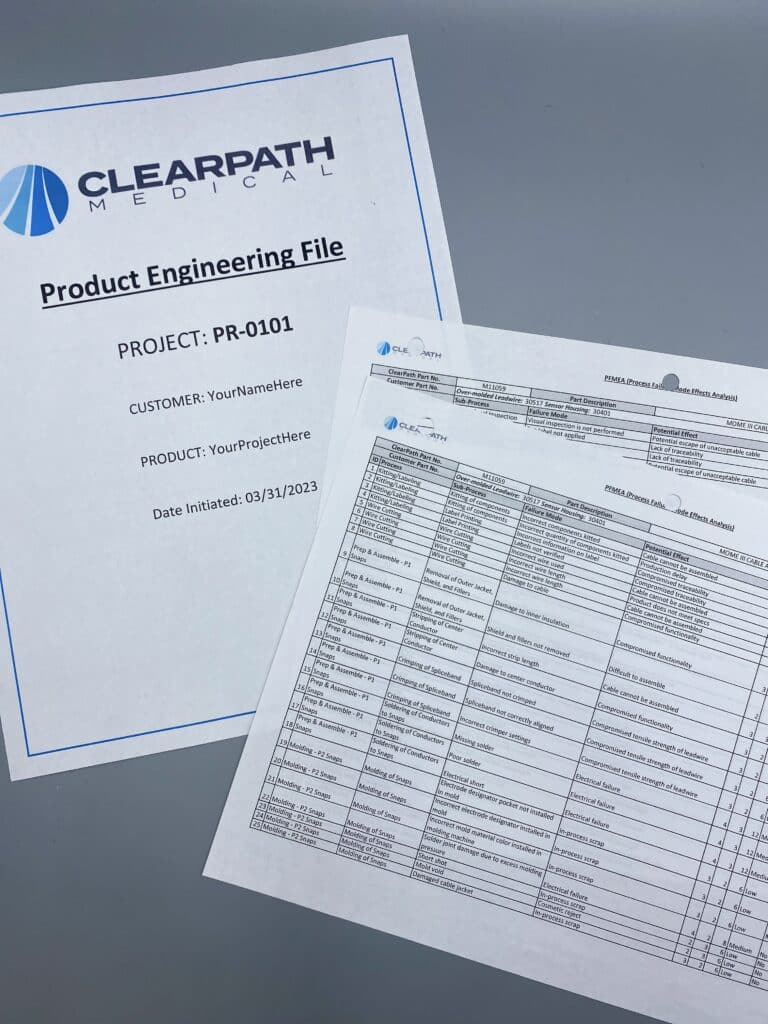

The Importance of PFMEA’s

PFMEA (Process Failure Mode and Effects Analysis) is an essential tool used in the medical device industry. PMFEA’s manage risks by identifying and reducing potential failure modes in the manufacturing process. This process helps manufacturers to prioritize their efforts to address the highest risk failure modes first and implement appropriate controls to mitigate risks to produce safe, high-quality products.

During inspections, the quality technicians check for potential failure modes identified in the PFMEA to make sure the controls are effective. If any issues are to be discovered, the PFMEA can then be updated, and the manufacturing process can be adjusted to prevent similar issues from reoccurring.

Integrating PFMEA’s into the inspection method of medical cable assemblies guarantees that the cable assemblies are safe and effective for use in critical medical applications. Manufacturers can continuously improve their manufacturing process and minimize the risks of product failure or defects that could harm patients by regularly updating and improving PFMEA’s.

Visual Inspections Per IPC and Cosmetic Defects

Visual inspection is an important aspect of quality control for medical devices. They are typically governed by industry standards from the International Electrotechnical Commission (IPC).

IPC-A-620 is an example of a standard that provides criteria for the acceptability of Cable and Wire Harness Assemblies and includes guidelines for visual inspection.

This process involves examining the device for any physical defects or irregularities that could affect its performance or safety. This could include inspecting the surface finish, color, markings, or any other visible characteristics of the device.

The IPC-A-620 standard provides specific guidelines for visual inspection based on the type and severity of the defect. For example, the standard specifies limits for the size and location of surface defects such as scratches, pits, and nicks. It also provides guidelines for the inspection of solder joints, which are commonly used in electronic medical devices.

Guidelines per IPC-A-620 for medical cable assemblies:

- Physical Characteristics of the Cable: Outlines the acceptable size, shape, color, and other physical characteristics of the cable.

This includes specifications for the thickness of:

- Insulation

- Jacket material

- Minimum bend radius

- Strain relief requirements

- Soldering of Connectors: Quality of solder joints in cable assemblies such as:

- Acceptable levels of wetting

- Fillet height

- Other criteria related to the quality such as presence of voids or cracks.

- Visual and Mechanical Characteristics: Visual and mechanical aspects of the cable assembly such as:

- Acceptable levels of surface defects (scratches or dents)

- Other criteria related to the mechanical strength of the assembly (pull force)

- Testing: IPC-A-620 also provides guidance on testing and inspection procedures like electrical testing to ensure proper signal transmission, as well as visual inspection to verify the quality of the assembly such as:

- Continuity testing

- Insulation resistance testing

- Dielectric withstanding voltage testing

- Cable flex testing

- Environmental testing

What is In-Process Testing?

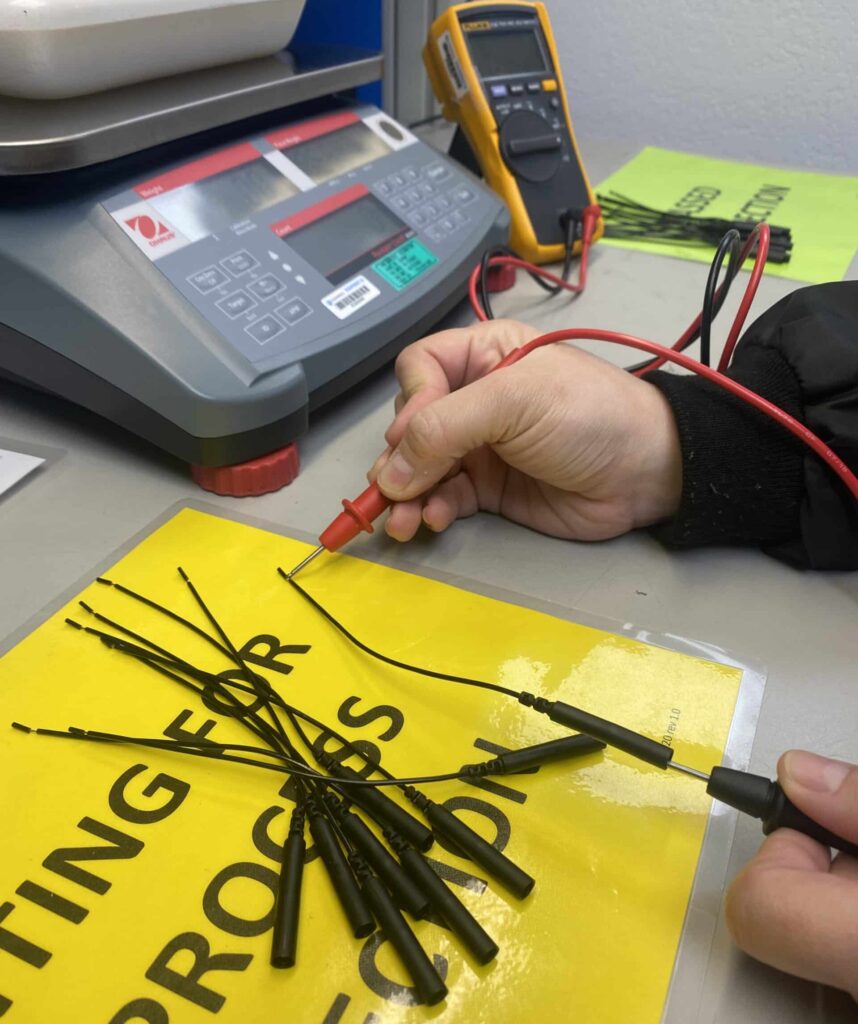

In-process testing involves conducting various tests during the manufacturing process to ensure that the products being produced meet the required quality standards. These tests include visual inspections, electrical testing, and process control. The purpose of this test is to catch issues early in the production process before the products are finished and sent out to customers.

Crimp Testing

This test that is performed on crimped connections of cables and wires. The purpose of crimp testing is to ensure that the crimped connection is reliable and will not fail under normal operation conditions.

Crimp Height Inspection – open barrel crimps

Crimp height inspection is the measurement of the crimped area from the top of the wire insulation to the top of the crimp. A crimp that is too high or too low can cause issues with the electrical connection or strain relief. During crimp height inspection, the crimp height is measured and compared to the specifications provided by the manufacturer to make sure that it falls within the acceptable range.

Pull Force Testing – closed barrel (machined) crimps

The purpose of pull force testing is so make sure that the crimped connection is able to withstand the mechanical stresses of the application. During testing, a calibrated pull tester is used to apply a predetermined force to the crimped connection. The force applied is gradually increased until the crimped connection fails or until the predetermined force is reached. The force required to cause the crimped connection to fail is recorded and compared to meet the specifications of the manufacturer and adheres to required standards.

Final Acceptance Testing

In addition to in-process testing, this testing is done after the products are finished to ensure that they meet the required quality standards before being shipped out to customers. Testing includes visual and final electrical.

Learn more about our Process Management here.

What Is Design Verification Testing?

While in-process testing and final acceptance testing are essential parts of the quality control process, there are other types of testing that are conducted prior to production release. Mechanical and environmental testing, as well as high voltage electrical testing, are design verification tests that are conducted to make sure that the inputs match the outputs.

Mechanical Testing

This type of testing involves putting a medical cable assembly through various forces and stresses to determine its strength, durability, and performance. Some types of mechanical testing include flex cycles, tensile strength, and mate/unmate testing.

During flex cycle testing, the medical assembly is repeatedly bent and flexed to determine its resistance to fatigue and failure over time. Tensile strength testing measures the amount of force that the assembly can withstand before it breaks, while mate/unmate testing assesses the cable assembly’s ability to withstand repeated connections and disconnections.

Environmental Testing

Environmental testing, on the other hand, involves exposing a product to various environmental conditions. The testing is designed to simulate the different environments that the cable assemblies may encounter during use, transportation, or storage.

The testing process can help identify potential issues with the cable assemblies that could impact their reliability, durability, or safety. For example, exposure to extreme temperatures or chemicals could damage the cable’s insulation or conductor materials, leading to a loss of electrical conductivity or insulation breakdown. Vibration and shock can also cause mechanical stresses that may affect the cable’s performance.

High-Voltage Electrical Testing

High-voltage electrical testing is another important test that is used to ensure that electrical components and systems are functioning correctly and can operate safely at high voltage levels. This type of testing challenges medical cables by subjecting them to high voltage electrical impulses to verify whether their insulation properties can withstand high voltage.

While these tests are important in verifying the design of a product, it is essential to note that they are not quality control tests.

Check out our previous blog: “The Recipe for Product Specifications” for more information on electrical and mechanical parameters.

Wrapping Things Up

Medical cable assemblies play a crucial role in delivering life-saving medical procedures and treatments, and ensuring their highest quality is essential to minimize the risks of product failure and defects that could harm patients. The use of PFMEA’s (Process Failure Mode and Effects Analysis) in the manufacturing process helps to identify and reduce potential failure modes, allowing manufacturers to prioritize their efforts and implement controls to minimize risks. Visual inspection per industry standards, such as IPC-A-620, is an essential aspect of quality control. In-process testing is done as process controls to confirm equipment setup. Final inspection occurs after products are finished to guarantee that everything is good to go before being shipped out to the customer. Meanwhile, design verification testing, such as mechanical and environmental testing, is conducted to ensure the product’s strength, durability, and performance. By integrating these methods into the inspection process, manufacturers can continuously improve their manufacturing process, minimize the risks of product failure, and ensure that the cable assemblies are safe and effective for use in critical medical applications.

Thanks for reading!

Contact Us for more information. We’re here to help. Let’s get started on your next medical cable assembly project, today!

Thanks for reading! Here are some more ClearPath Medical blogs that might interest you.

Love what you see? Sign up for our newsletter to get the latest updates on our company, worldwide and more.