Overmolding: Encapsulated Electronics

Medical devices are highly sophisticated devices that are used in critical patient care. These elaborate systems need specialized cable assemblies to deliver precise signals and power. By the process of overmolding encapsulated electronics, these sensitive components are protected.

Overmolded Electronics

There are crucial components built into medical cable assemblies that allow the transfer of data and power within the cable. These components are:

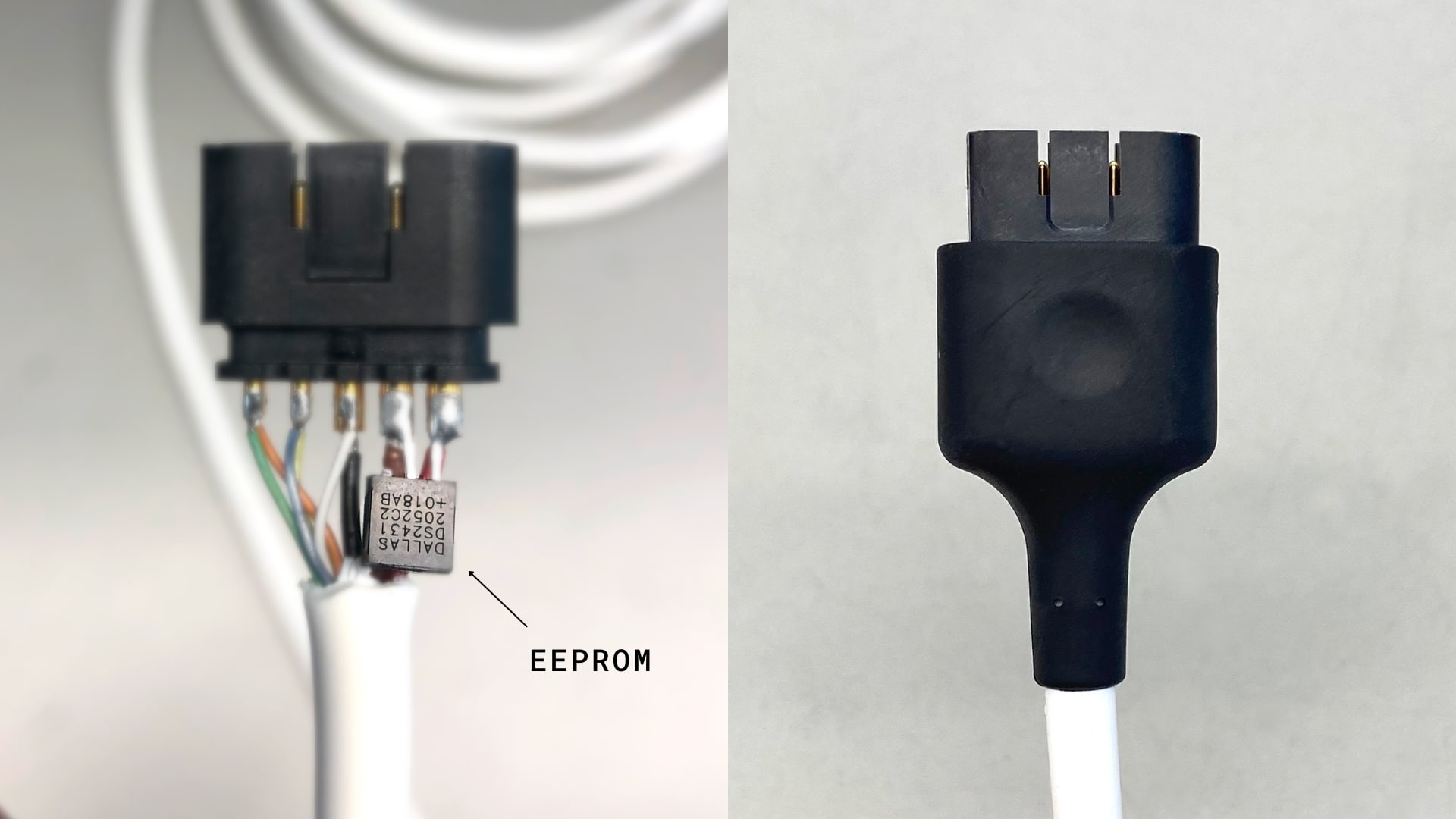

Electrically Erasable Programmable Read-Only Memory (EEPROM): These are non-volatile memory chips that can store data even when there is no power. Their role in medical devices is to calibrate data, serial numbers and configure settings. EEPROMs allow for easier and faster setup of the device while providing accurate and reliable measurements.

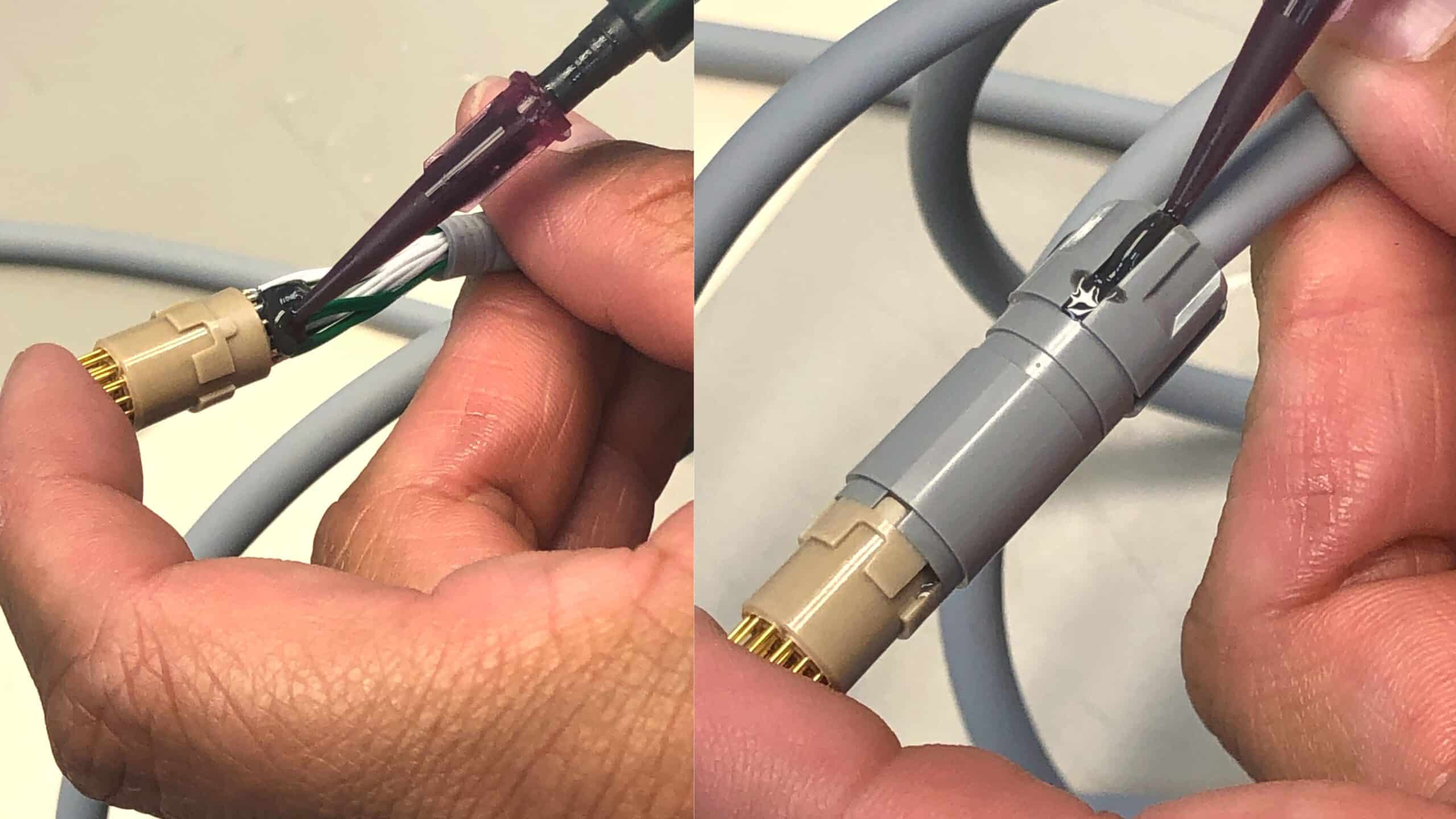

Printed Circuit Board Assemblies (PCBA’s): PCBA’s are used in medical cable assemblies to provide electrical connections between different components. PCBA’s are complete circuit boards containing necessary components and electrical connections for functions within the medical device. They enable the device to perform its intended function. PCBA design and manufacturing must comply with strict regulatory standards that it meets the safety and efficacy of the device.

From precise routing and connections to storing important data, the protection of PCBAs and EEPROMs in medical cable assemblies is important to ensure safety and reliability.

Figure 1: EEPROM before and after encapsulation

Figure 2: PCBA before and after encapsulation in its premold stage

Why Electronics Should be Overmolded

Choosing to encapsulate electronics is decided when cable assemblies are required to meet Ingress Protection guidelines. This is an additional measure to protect the electronics from any exposure to dirt, dust, water etc. By protecting the sensitive electronic components, overmolding helps extend the life of the device and reduce long-term costs.

Factors to Consider

Encapsulation is a process that requires entrapping electrical components with resin. So, when it comes to overmolding electronics in the medical cable assembly industry, it’s important to take into consideration the different methods, materials, and their advantages.

Encapsulation Material

The material used for encapsulation must be carefully selected based on the specific needs of the medical cable assembly. Factors such as the intended use of the device, the expected environmental conditions, and the required electrical properties should be considered when selecting the material.

Materials

Typically, encapsulating electronics requires specific materials. It’s important to note that not every material will work best to overmold electronics, but knowing which ones work best for specific medical cable assemblies will have the most optimal performance.

- Silicone: Silicone is a flexible, high-performance material that is often used in medical cable assemblies. It provides excellent resistance to high temperatures, UV light, and chemicals, making it suitable for a wide range of applications.

- Polyurethane: Polyurethane is a versatile material that is used in a variety of medical applications. It provides excellent resistance to abrasion and impact, making it suitable for applications where the device may be subjected to harsh conditions.

- Epoxy: Epoxy is a strong, durable material that provides excellent electrical insulation and resistance to chemicals. It is often used in applications where the device may be exposed to harsh chemicals or solvents.

- Acrylic: Acrylic is a rigid, high-performance material that is often used in medical cable assemblies. It provides excellent resistance to impact and can withstand high temperatures.

Manufacturing Process

The manufacturing process for overmolding encapsulated electronics in medical cable assemblies should be carefully planned to ensure the encapsulation is applied evenly and with the correct amount of pressure.

The Encapsulation Processes

Choosing the best encapsulation method depends on size, durability, ingress protection requirements, cost, development time and the look and feel of the final assembly.

There are typically four different processes that ensure the safety of the medical device electronics. Each process requires different materials and is specific to its intended use:

- Overmolding: Encapsulating the electronic components in a thermoplastic or thermosetting material using a mold. The mold is designed to fit the shape of the medical cable assembly and ensure that the encapsulation material is distributed evenly. This method provides excellent environmental protection.

- Clamshell: This method involves enclosing the electronic components in a preformed plastic shell that is attached to the medical cable assembly. This method is often used for devices that have limited space and cannot accommodate traditional overmolding.

- Hybrid: This method combines overmolding and clamshell techniques to provide the best of both worlds. The electronic components are encapsulated using overmolding, and a preformed plastic shell is attached to the overmolded part to provide additional protection.

- Coating and potting: Coating involves applying a thin layer of protective material over the electronic components. This method is often used for devices that have limited space or require a high degree of flexibility and completely encapsulates the electronic components in a resin material. Potting is a method that provides excellent protection from environmental factors but may be less suitable for devices that require a high degree of flexibility.

Figure 3: (Left) Clamshell with overmold hybrid, (Right) Overmolded yoke assembly

Figure 4: Potting

Benefits to Encapsulations

Overmolding encapsulated electronics in medical cable assemblies provides an array of benefits for both the device and the end-user. By protecting sensitive electronic components, overmolding can help enhance the device’s durability, reliability, safety, and more.

- Durability: Protective layers, reducing frequent repairs/replacements.

- Reliability: Helps prevent accidental damage.

- Protection: Helps to prevent exposure to environmental factors. See IP.

- Flexibility: Medical cables adapting to different environments and applications.

- Better performance: Prevent electrical contact; reduce electrical malfunctions.

- Aesthetic: Smooth and uniform surface finish that enhances appearance of medical cable assemblies.

Our capabilities

Here at ClearPath Medical, we understand the distinct challenges and requirements of the medical industry, which is why we offer a range of overmolding techniques. We are an extension of your team and will work closely with you to determine the best approach for your project based on your specific needs. We are fully dedicated to delivering the highest quality products and services to our clients, and we prioritize attention to detail, precision, and reliability. With our extensive knowledge and expertise in overmolding encapsulated electronic components for medical cable assemblies, you can be confident that your project is in excellent hands.

We’re here to help. Contact us to learn more.

Thanks for reading! Here are some more ClearPath Medical blogs that might interest you.

Love what you see? Sign up for our newsletter to get the latest updates on our company, worldwide and more. Be sure to also follow us on LinkedIn for company updates, news, and more!